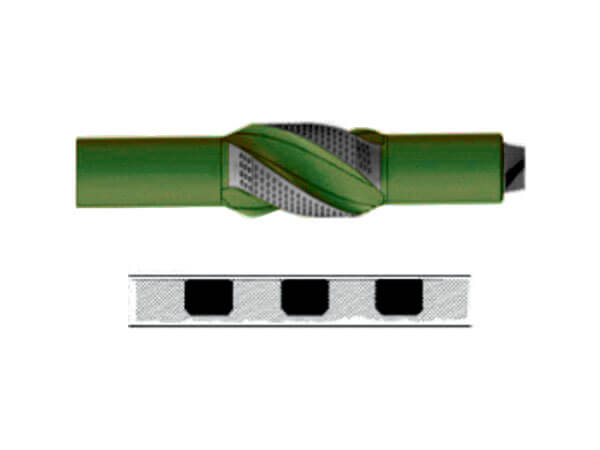

HF 1000

Our hardfacing solutions provide a cost-effective, durable, and hard-wearing solution suitable for softer to medium formations. The composite rod features 1/8" to 1/4" crushed tungsten wear carbides, bonded in a tough nickel-based matrix, ensuring long-lasting protection. We also offer variations in cutting carbides tailored for milling and scraping applications, enhancing tool performance in challenging environments.